Die Mould Manufacturer for Precision Industrial Applications

Die Mould Manufacturer in Mumbai Delivering Reliable Industrial Tooling

Mumbai stands as one of India’s most powerful manufacturing hubs, driving continuous demand for a dependable die mould manufacturer in Mumbai. Key sectors such as automotive, FMCG, packaging, electricals, and plastics depend heavily on precision-engineered dies and moulds to ensure dimensional accuracy, product uniformity, and smooth large-scale production.

A professional die and mould manufacturer in India plays a crucial role in reducing rejection rates, improving cycle times, and maintaining consistent output across high-volume manufacturing environments. Precision tooling directly impacts profitability, efficiency, and long-term production stability.

Importance of Choosing the Right Mould Manufacturing Company

Selecting the right mould manufacturing company in Mumbai is a strategic decision that affects product quality and operational efficiency over time. Experienced moulds and dies manufacturers focus on engineering accuracy, robust material selection, and process optimisation rather than short-term cost savings.

A reliable partner ensures:

- Reduced downtime due to tooling failures

- Longer mould life and consistent performance

- Lower maintenance and replacement costs

- Improved product finish and dimensional accuracy

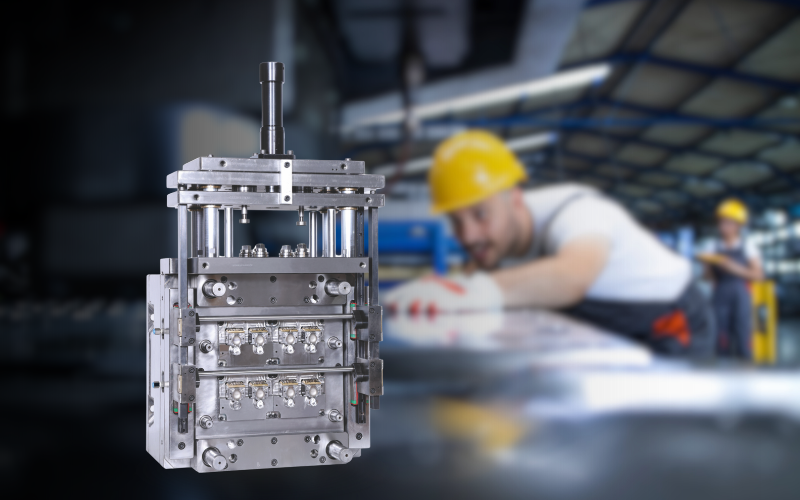

Key Capabilities of a Reliable Mould Manufacturer Company

A trusted mould manufacturer company is defined by its technical strength and process discipline. Core capabilities include:

- Advanced CAD/CAM-based design for precise tooling development

- High-accuracy CNC machining to meet tight tolerances

- Use of premium-grade tool steels for durability and wear resistance

- Strict quality inspection protocolsat every production stage

- Proven multi-industry experienceacross automotive, plastics, and packaging sectors

These capabilities ensure moulds perform consistently under high pressure, temperature variation, and continuous production cycles.

Role of Mould and Die Manufacturers in Modern Manufacturing

Professional mould and die manufacturers are integral to modern industrial production. High-quality tooling supports mass manufacturing by ensuring repeatability, faster cycle times, and minimal material wastage.

Well-engineered moulds directly influence:

- Production speed and efficiency

- Surface finish and product aesthetics

- Machine life and operational safety

- Overall cost per unit in large-scale manufacturing

Engineering Expertise That Supports Industry Needs

Ananta Moulds India follows a quality-driven and engineering-focused approach to deliver custom-designed dies and moulds tailored to specific application requirements. Each project is developed with close attention to material selection, tooling accuracy, and real-world production conditions, ensuring reliable performance across industries.

Conclusion

With a strong emphasis on precision engineering, durability, and long-term performance, Ananta Moulds has established itself as a trusted die mould manufacturer in Mumbai. By delivering consistent, high-quality tooling solutions, the company helps manufacturers enhance productivity, reduce operational risks, and achieve dependable manufacturing outcomes across diverse industrial applications.