Oil And Lubricants Industry

Download E-Catalogue

View E-Catalogue

Enquire Now

Ensuring your oil and lubricant containers are securely sealed and easy to use is crucial for both product protection and customer satisfaction. At Ananta Moulds Pvt. Ltd., we offer a comprehensive range of cap and flip top mould solutions specifically designed for the oil and lubricants industry.

We are a leading moulds manufacturer in India, specializing in moulds and dies for plastic caps and closures. Whether you need standard closures or custom designs, we have the expertise and technology to deliver high-quality moulds that meet your exact requirements.

Looking for "Moulds for Oil & Lubricant Packaging"?

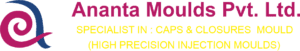

04CV Deo Cap Inside Gate

CAP INSIDE GATE mould is a specialized tool designed for creating specific types of caps, potentially related to legal or court documents.

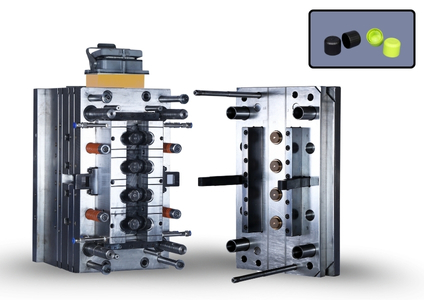

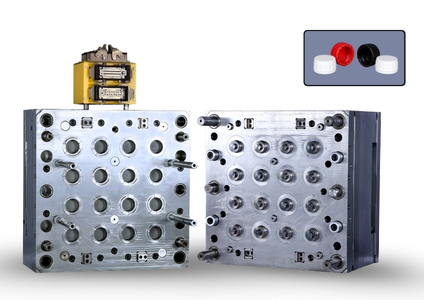

32CV Dia Crc Inner Cap

This mould set creates a two-piece Child Resistant Closure (CRC) system, ideal for packaging products that require extra safety measures.

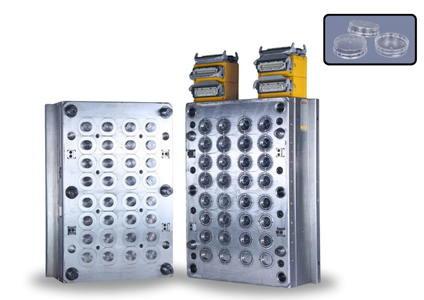

32CV-25 MM-Ropp Cap

This mould creates Roll-On Pilfer Proof (ROPP) caps, commonly used for products like serums or toners. closure system offers tamper evidence.

32CV-15DIA Unscrewing Flip Top Cap

This mould produces a convenient and tamper-evident flip top cap, ideal for syrups, sauces, condiments.

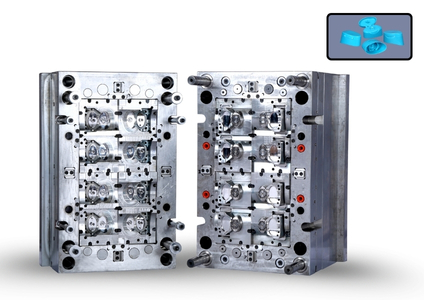

08CV Oval Flip

Top Cap

This mould creates a unique oval-shaped flip top cap, perfect for adding a touch of elegance to cosmetic containers.

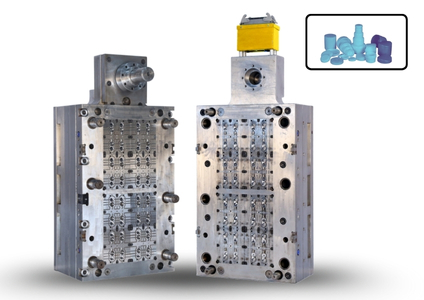

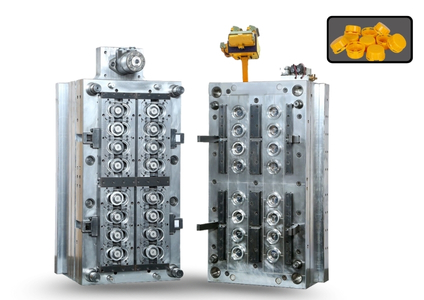

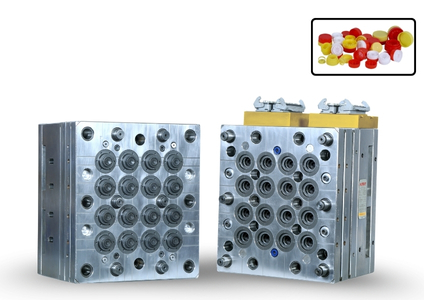

16CV-(38-23) Lub Oil Cap Mould

This mould produces a cap specifically designed for lubricants and oil containers, ensuring a secure closure .

16CV Nylon Cap Gear Mould

These moulds produce essential components for various cap designs, including those used with flip tops.

16CV-CTC Flower Cap Mould

The 16CV-CTC Flower Cap Mould is a premium, precision-engineered tool designed decorative flower-shaped caps.

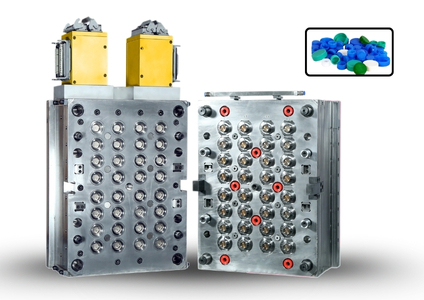

48CV Water Cap Mould

The 48CV-Water Cap Mould is a state-of-the-art tool designed specifically for producing high-quality water bottle caps.

End Products of Oil And Lubricants Industry

FAQ

- Experience and Expertise: As a leading mold manufacturer of plastic bottle caps, we have extensive experience in designing and manufacturing high-quality molds for the oil and lubricants industry.

- Focus on Customization: We understand that your packaging needs are unique. Our customized cap mold manufacturer capabilities allow us to tailor molds to your specific product characteristics and desired functionality.

- Durable and Long-lasting Molds: We use top-grade materials and employ precision engineering to ensure our molds are built to last, delivering consistent, high-quality caps throughout their lifespan.

- Reliable Support: Our team of experts is here to assist you in choosing the right mold for your oil and lubricant containers and answer any questions you may have about plastic molding machine manufacturers or Die Mould Manufacturers.