FMCG Industry

Ananta Moulds offer’s a wide range of flip top cap mould options to suit your specific needs, ensuring functionality, efficiency, and a touch of style for your products. Whether you’re in the FMCG (Fast Moving Consumer Goods) industry or another sector that utilizes flip top caps, we have the mould solutions for you.

Benefits of Customized Moulds:

- Enhanced Product Design: Bring your most creative ideas to life with moulds precisely engineered to your specifications. From intricate shapes to complex functionalities, our custom moulds ensure your product stands out on the shelf.

- Improved Production Efficiency: Optimize your production line with moulds tailored for your specific materials and processes. Reduced cycle times and minimized waste translate to significant cost savings and faster time-to-market.

- Superior Product Quality: Our high-precision moulds deliver consistent, top-quality results every time. Minimize defects and ensure a flawless finish for your FMCG products, boosting customer satisfaction and brand reputation.

- Material Versatility: We work with a wide range of materials suitable for the FMCG industry, including plastics, metals, and composites. Choose the optimal material for your product’s specific requirements, ensuring durability, functionality, and cost-effectiveness.

Custom Mould Options for FMCG Industry Applications:

- Injection Moulding: Our high-pressure injection moulding technique is ideal for mass-producing a wide variety of FMCG products, from containers and closures to toys and personal care items.

- Blow Molding: Create lightweight, hollow plastic containers for beverages, food items, and household products with our efficient blow molding solutions.

- Compression Molding: This versatile process is perfect for producing complex shapes and thick-walled components commonly found in FMCG goods.

- Thermoforming: Manufacture cost-effective packaging solutions and disposable products with our precise thermoforming molds.

Looking for "Moulds for FMCG Industry"?

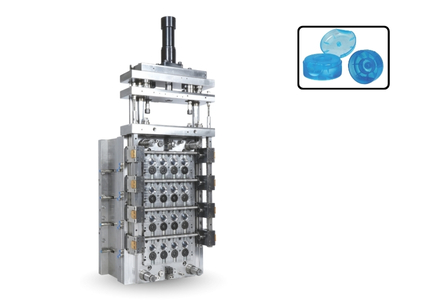

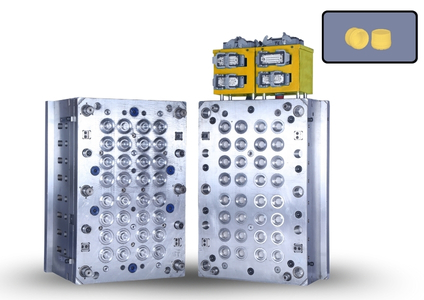

16CV-Flip Top (50 Dia Autoclosing Flip Top)

The 16CV-Flip Top (50 Dia Autoclosing Fliptop) offers secure, spill-proof sealing with an easy autoclosing design.

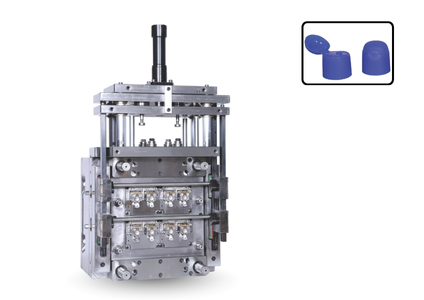

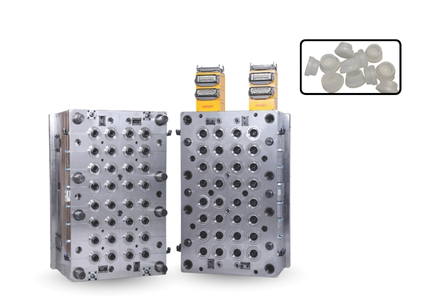

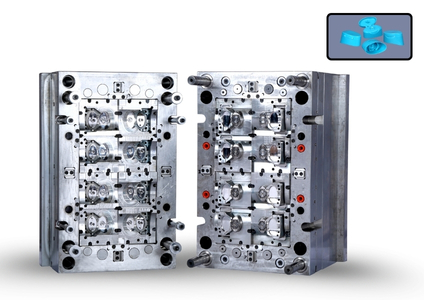

08CV-Flip Top (Rhino Flip Top Cap)

The 08CV-Flip Top (Rhino Flip Top Cap) offers leak-proof, easy one-handed dispensing, perfect for industrial and consumer use

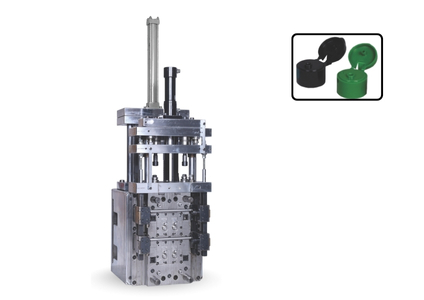

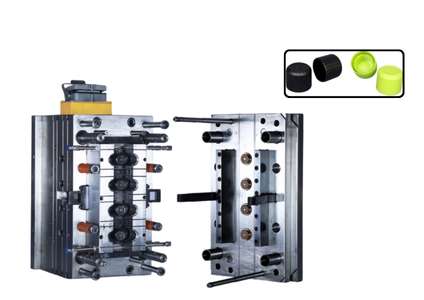

04 CV-Flip Top (24 Dia Autoclosing Fliptop)

04 CV-Flip Top (24 Dia Autoclosing Fliptop)) offers secure, spill-proof sealing with an easy autoclosing design.

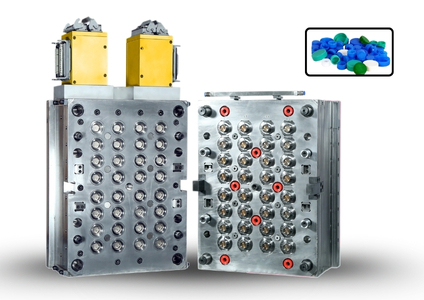

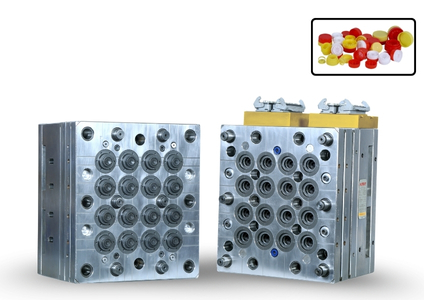

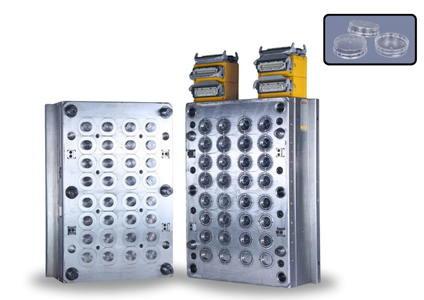

32CV Beverage cap Mould

The 32CV- Beverage cap Mould is a state-of-the-art tool designed specifically for producing high-quality Beverager bottle caps.

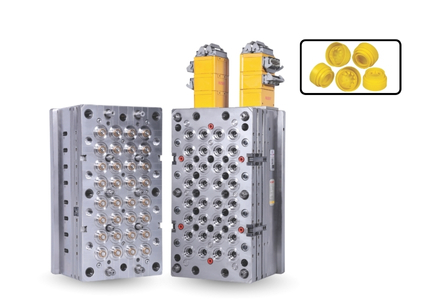

48CV Beverage cap

The 48CV Beverage cap is a durable and reliable solution for precise Beverage sealing in industrial and mechanical systems.

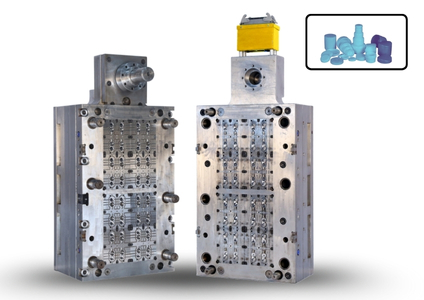

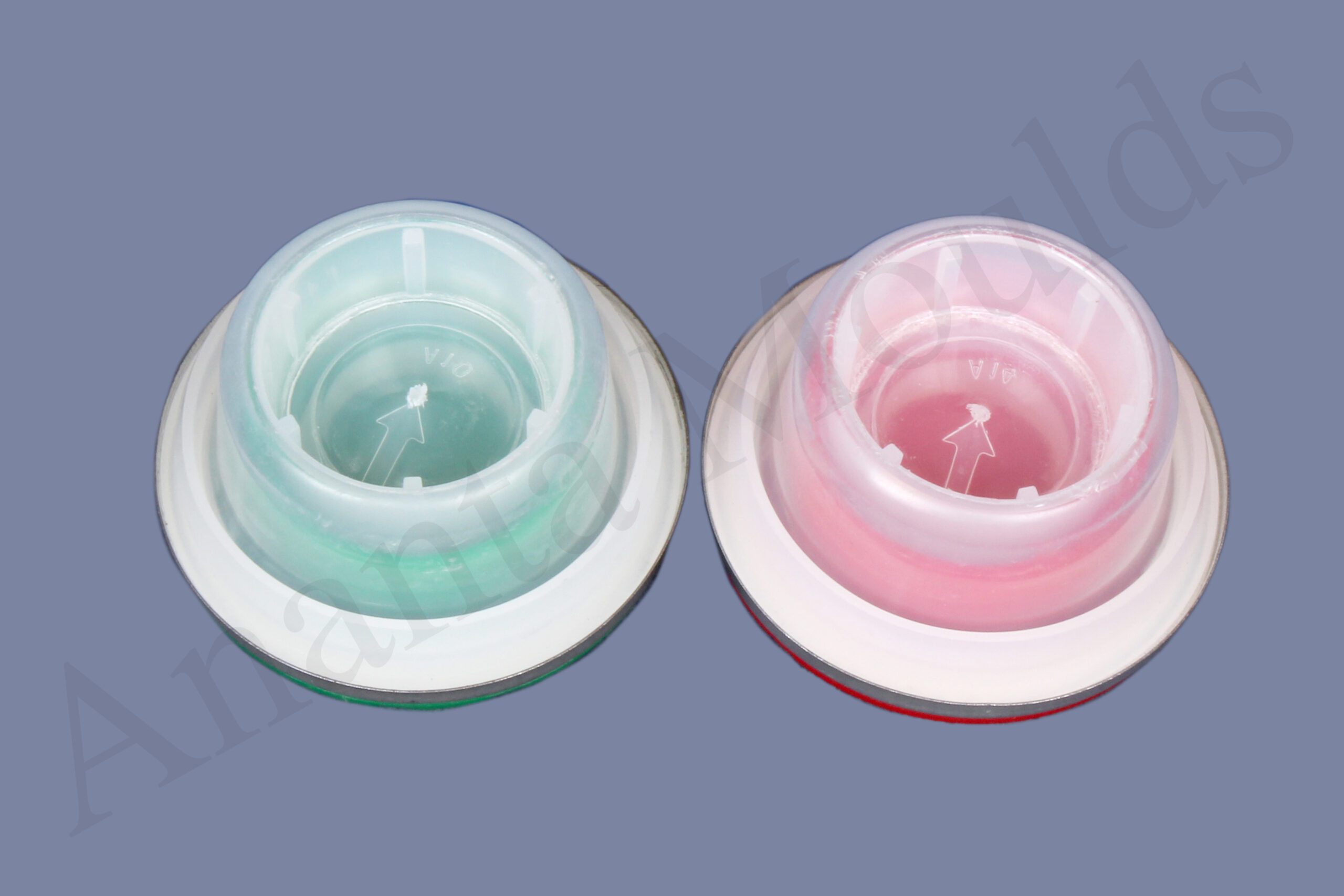

32CV-Spout Bottom

The 32CV-Spout Bottom ensures reliable, leak-proof fluid handling with durable construction for consistent industrial performance.

32 CV 42 Dia 20 Ltr Spout Top Cap

Our CTC Spout Top Cap Mould is designed for manufacturers who demand exceptional accuracy, durability, and consistency in high-volume cap production.

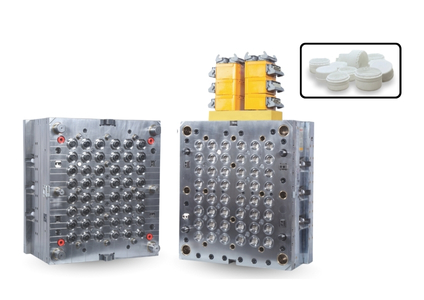

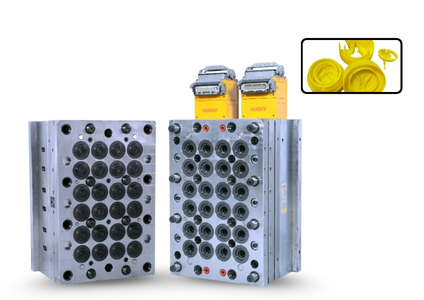

16CV-CTC Flower Cap Mould

The 16CV-CTC Flower Cap Mould is a premium, precision-engineered tool designed to produce decorative flower-shaped caps.

32CV-15DIA Unscrewing Flip Top

The 32CV-15DIA Unscrewing Flip Top Cap Moulds Manufacturer is a high-performance tool designed for producing flip-top bottle caps with an unscrewing feafwaterture.

32CV-25 MM-Ropp Cap

This mould creates Roll-On Pilfer Proof (ROPP) caps, commonly used for products like serums or toners.

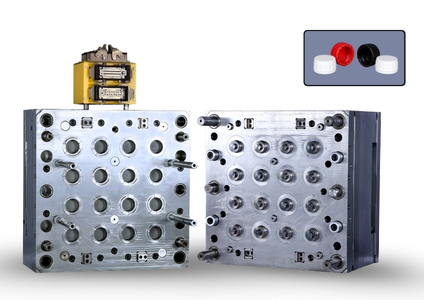

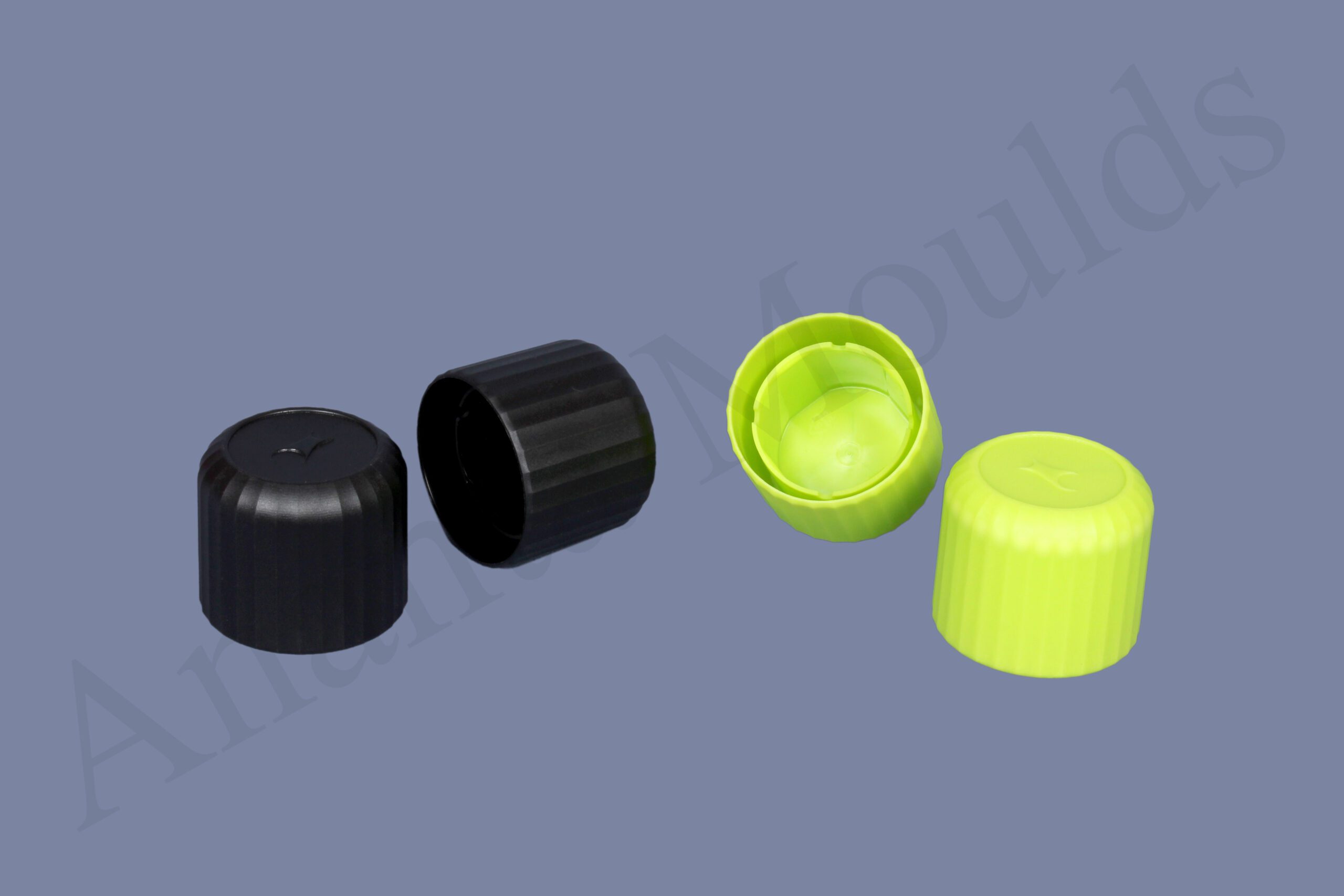

32CV Dia Crc Inner Cap

This mould set creates a two-piece Child Resistant Closure (CRC) system, ideal for packaging products that require extra safety .

24CV-CTC Double Flow

The 24 CV-CTC Double Flow valve ensures smooth dual-direction flow with durable, precise performance for industrial applications

16CV-(38-23) Lub Oil Cap Mould

This mould produces a cap specifically designed for lubricants and oil containers, ensuring a secure closure .

08CV Oval Flip Top Cap

This mould creates a unique oval-shaped flip top cap, perfect for adding a touch of elegance to cosmetic containers.

04CV Deo Cap Inside Gate

The inside gate design ensures a seamless finish with smooth caps, while the premium-grade steel construction.

32CV-CTC Flower Cap

The 32CV-CTC Flower Cap delivers reliable, precise performance in demanding industrial and commercial environments.

End Products of FMCG Industry

FAQ

- Mould Manufacturer Expertise: We are a leading molds and dies manufacturer with extensive experience in the Indian market. Our expertise ensures high-quality, durable molds that meet your specific requirements.

- Focus on Customization: We understand that your cosmetic brand deserves unique packaging. That’s why we offer customized cap mold options, allowing you to tailor the design and functionality of your caps to perfectly match your brand identity.

- Competitive Lead Times: We strive to deliver your molds efficiently, ensuring you can launch your cosmetic products on time.

- Unwavering Quality: We use top-grade materials and employ meticulous engineering processes to create molds that produce consistent, high-quality caps for your cosmetic line.

- Mould Manufacturer Expertise: We are a leading molds and dies manufacturer with extensive experience in the Indian market. Our expertise ensures high-quality, durable molds that meet your specific requirements.

- Focus on Customization: We understand that your cosmetic brand deserves unique packaging. That’s why we offer customized cap mold options, allowing you to tailor the design and functionality of your caps to perfectly match your brand identity.

- Competitive Lead Times: We strive to deliver your molds efficiently, ensuring you can launch your cosmetic products on time.

- Unwavering Quality: We use top-grade materials and employ meticulous engineering processes to create molds that produce consistent, high-quality caps for your cosmetic line.

By partnering with us, you gain access to a reliable and experienced Die Mould Manufacturer in India. We are dedicated to helping you elevate your cosmetic packaging and achieve success in the competitive beauty market.