Injection molding is a critical manufacturing process used across various industries, including automotive, medical, consumer products, packaging, and aerospace. This comprehensive guide will explore everything you need to know about injection molds and the injection molding process, providing valuable insights into their applications, components, and operational principles.

What Are Injection Molding Used For?

Injection molds are essential tools used in the injection molding process to produce a wide range of parts and products. Here’s how they are utilized in different industries:

Automotive

In the automotive industry, injection molds are used to create various components such as dashboards, bumpers, Flip Top Caps Mold, Plastic Bottel Mold and interior panels. These parts must meet high standards of precision and durability to ensure vehicle safety and performance.

Medical

The medical field relies on injection molds for producing medical devices, surgical instruments, Flip Top Caps Mold, Plastic Bottel Mold and diagnostic equipment. These components often require stringent regulatory compliance and sterile manufacturing conditions.

Consumer Products

From household goods to electronics, injection molds are employed to manufacture products like plastic containers, toys, Flip Top Caps Mold, Plastic Bottel Mold and electronic housings. This process allows for mass production of high-quality, consistent items.

Packaging

Injection molding is crucial in the packaging industry for producing items such as bottle caps, containers, Flip Top Caps Mold, Plastic Bottel Mold and lids. The method ensures these products are lightweight, durable, and can be produced in large quantities.

Aerospace

The aerospace industry utilizes injection molding to create lightweight, high-strength components for aircraft and spacecraft. These parts must withstand extreme conditions and rigorous testing standards.

What is Injection Molding?

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold. The materials commonly used include thermoplastics, thermosetting plastics, metals, and ceramics. The process is highly efficient and capable of producing complex shapes with tight tolerances.

Benefits of Injection Molding

- High Efficiency: Once the initial mold is created, the production cycle is swift, allowing for mass production.

- Precision and Consistency: Injection molding produces parts with high accuracy and uniformity.

- Material Versatility: The process can handle a vast array of materials, making it suitable for diverse applications.

- Complex Geometries: Injection molding can create intricate designs that would be challenging or impossible with other manufacturing methods.

What is the Working Principle of Injection Molding?

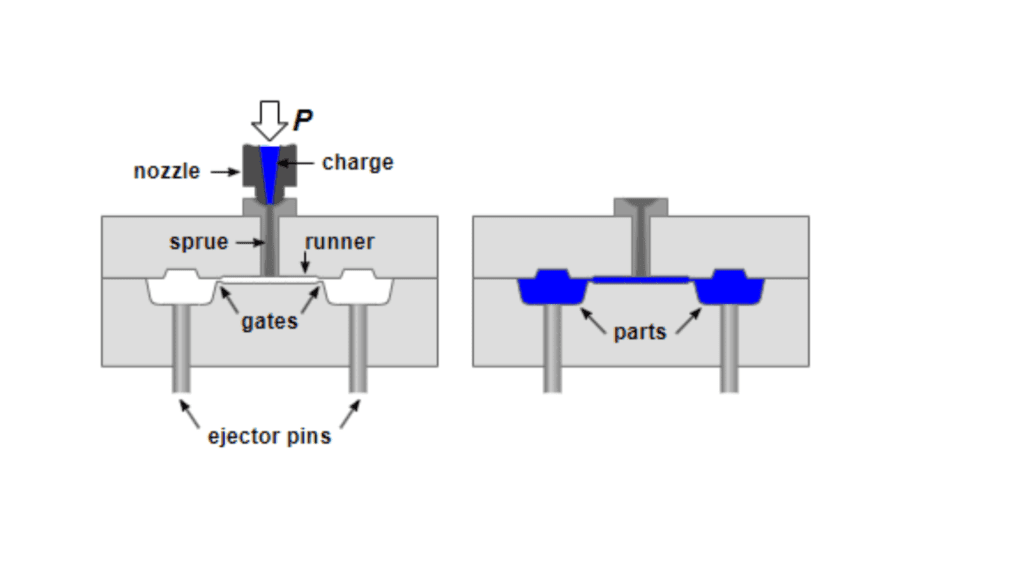

The injection molding process follows a series of steps to transform raw material into a finished product. Here’s a breakdown of the working principle:

Step 1: Clamping

The process begins with the clamping unit securing the two halves of the mold together. A hydraulic or mechanical clamping force keeps the mold tightly closed during the injection phase.

Step 2: Injection

Next, raw material is fed into the injection molding machine via a hopper. The material is heated to a molten state within the barrel, where a reciprocating screw or ram injects it into the mold cavity. The pressure and speed of injection are carefully controlled to fill the mold completely.

Step 3: Cooling

Once the material fills the mold, it begins to cool and solidify. Cooling channels within the mold help dissipate heat, ensuring the part hardens evenly and minimizes the risk of defects.

Step 4: Ejection

After the part has sufficiently cooled, the mold opens, and the ejection system pushes the finished product out of the mold cavity. Ejector pins or plates facilitate this process, and the mold is then ready for the next cycle.

What Are the 3 Main Parts of the Injection Mold?

Injection molds are complex tools that consist of several components, but three main parts are crucial for their function:

1. Mold Base

The mold base serves as the foundation of the injection mold. It includes the clamping plates and support structures that hold the entire mold assembly together. The mold base provides structural integrity and ensures precise alignment during the molding process.

2. Core and Cavity

The core and cavity are the parts of the mold that directly shape the final product. The cavity is the hollow space into which the molten material is injected, while the core forms the internal features of the part. The design of the core and cavity is critical to achieving the desired part geometry and quality.

3. Ejector System

The ejector system is responsible for removing the finished part from the mold. Ejector pins or plates push the part out of the cavity once the material has solidified. The system must be carefully designed to avoid damaging the part during ejection.

Conclusion

Injection molds and the injection molding process are indispensable in modern manufacturing, enabling the production of high-quality, complex parts across various industries. Understanding the applications, principles, and components of injection molds provides valuable insights into their role in today’s industrial landscape.

By leveraging the efficiency, precision, and versatility of injection molding, businesses in automotive, medical, consumer products, packaging, and aerospace sectors can achieve greater productivity and innovation.