Plastic caps are ubiquitous across a variety of industries, including the beverage, food, pharmaceutical, chemical, personal care, and industrial sectors. They serve as crucial components in packaging, ensuring product safety and integrity while also offering convenience to consumers. But what goes into making these essential items? This blog post delves into the intricacies of plastic cap molding, providing valuable insights into the processes, materials, and types of plastics involved.

What is the Process of Making Plastic Caps?

The process of making plastic caps involves several steps, primarily focused on molding, a method that shapes plastic by melting it and then injecting or compressing it into a mold. Here’s an overview of the typical steps involved:

- Design and Prototype: The process begins with designing the cap and creating a prototype, often using CAD software. This step allows for testing and refinement before mass production.

- Material Selection: Choosing the right type of plastic based on the cap’s intended use and required properties.

- Molding: The selected plastic material is melted and then injected or compressed into a mold. Various molding techniques can be used, which we will discuss later.

- Cooling and Ejection: Once the plastic has filled the mold, it is allowed to cool and harden. The hardened cap is then ejected from the mold.

- Finishing: Post-molding processes such as trimming, drilling, or adding additional features like threads or seals may be required.

- Quality Control: Each cap undergoes stringent quality checks to ensure it meets industry standards and specifications.

What Plastic is Used for Molding?

The type of plastic used for molding depends on the specific requirements of the cap, such as flexibility, durability, chemical resistance, and cost-efficiency. Common plastics used in cap molding include:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Polystyrene (PS)

- Acrylonitrile Butadiene Styrene (ABS)

What are the Three Types of Molding?

Three primary types of molding processes are used in the production of plastic caps:

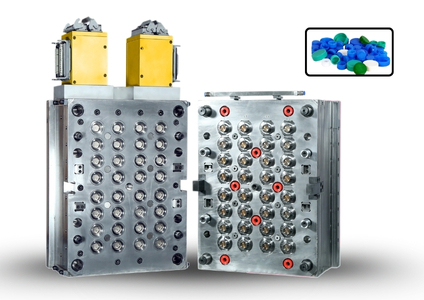

- Injection Molding: This is the most common method, where melted plastic is injected into a mold under high pressure. It’s ideal for producing high volumes of complex-shaped caps with precise dimensions.

- Compression Molding: In this process, a pre-measured amount of plastic is placed into a heated mold cavity. The mold is then closed, and pressure is applied to form the cap. It’s often used for larger, simpler caps.

- Blow Molding: This technique involves inflating melted plastic inside a mold to form hollow parts. It’s commonly used for producing bottle caps and other hollow components.

What are the 7 Main Types of Plastic?

Understanding the types of plastic is crucial for selecting the right material for cap molding. Here are the seven main types:

- Polyethylene Terephthalate (PET): Commonly used for beverage bottles and food containers.

- High-Density Polyethylene (HDPE): Known for its strength and chemical resistance, making it ideal for industrial products.

- Polyvinyl Chloride (PVC): Used in a variety of applications, from pipes to packaging.

- Low-Density Polyethylene (LDPE): Flexible and used for bags, wraps, and some bottles.

- Polypropylene (PP): Resistant to chemicals and heat, making it suitable for food containers and automotive parts.

- Polystyrene (PS): Used for disposable containers and insulation.

- Other Plastics: Includes nylon, acrylic, and bioplastics, among others.

What is Basic Molding Material?

The basic molding material is plastic resin, which is chosen based on the required properties of the final product. Resins are typically classified by their polymer structure and can be thermoplastic or thermoset. Thermoplastics, such as PE and PP, become pliable when heated and hardened upon cooling, making them ideal for various molding processes. Thermosets, on the other hand, harden permanently after being heated.

What Type of Plastic is PVC?

Polyvinyl Chloride (PVC) is a versatile thermoplastic used in a wide range of applications. It’s known for its durability, chemical resistance, and cost-effectiveness. PVC can be rigid, as in pipes and building materials, or flexible, as in films and soft packaging. Its adaptability makes it a popular choice for many industries.

What are PP and PE Plastic?

Polypropylene (PP) and Polyethylene (PE) are two of the most commonly used plastics in molding:

- Polypropylene (PP): PP is a thermoplastic polymer known for its toughness, chemical resistance, and insulating properties. It is widely used in packaging, automotive, and consumer goods.

- Polyethylene (PE): PE is another thermoplastic polymer, available in various densities (HDPE, LDPE, and LLDPE). It is valued for its versatility, impact resistance, and ease of processing. PE is commonly used in packaging, containers, and household products.

What Type of Plastic is HDPE?

High-Density Polyethylene (HDPE) is a thermoplastic polymer characterized by its high strength-to-density ratio. It is known for its excellent chemical resistance, toughness, and durability. HDPE is used in a wide range of applications, including:

- Containers and bottles for food and beverages

- Industrial drums and containers

- Pipes and fittings

- Plastic lumber and outdoor furniture

Conclusion

Plastic cap molding is a sophisticated process that leverages advanced materials and techniques to meet the diverse needs of the beverage, food, pharmaceutical, chemical, personal care, and industrial sectors. Understanding the different plastics, molding methods, and material properties is crucial for selecting the right approach for your specific application.

Whether you’re in the business of packaging beverages or pharmaceuticals, embracing the right plastic cap molding techniques can significantly enhance the quality and functionality of your products. By staying informed and adapting to evolving technologies, you can ensure your products remain competitive and meet the highest standards of safety and efficiency.